Building spacecraft that can survive the heat of reentry by “sweating” a thermally protective layer of gas has been a dream of aerospace engineers for 50 years. Now an Air Force Research Laboratory grant aims to make that a reality.

Transpiration cooling, as the sweating process is more formally known, is the key to designing truly reusable spacecraft and hypersonic vehicles, Hassan Saad Ifti, an assistant aerospace engineering professor at Texas A&M University, told Air & Space Forces Magazine.

The school is sharing a $1.7 million grant with Canopy Aerospace, a Colorado-based advanced materials-manufacturing startup, to produce a model vehicle to test transpiration technology for a variety of applications, including atmospheric flight and reentry from orbit. AFRL awarded the grant in August, and the team hopes to have a model for static testing ready by the end of the year, Ifti said.

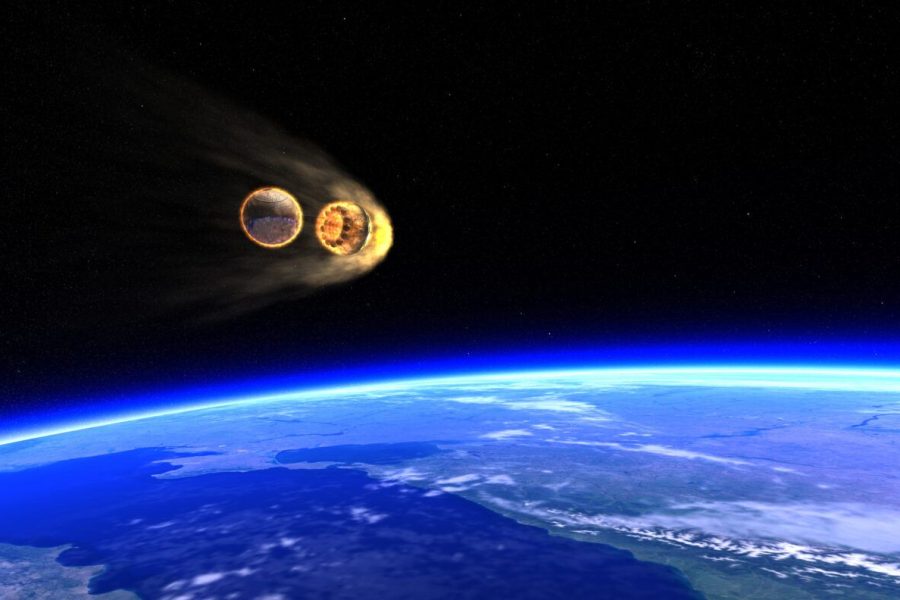

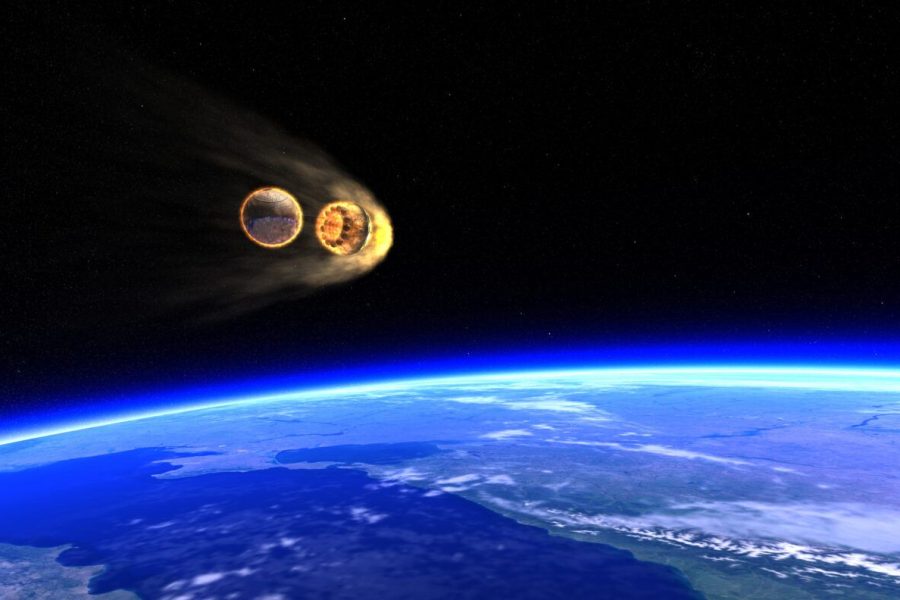

Transpiration cooling occurs when pressurized fluid spewed from the front of a hypersonic vehicle instantly evaporates, forming a protective layer of gas that insulates against the extreme heat generated by friction between the vehicle and the atmosphere, according to Canopy. It is “one of the only researched technologies that could enable true reusability for mass return from orbit on ballistic trajectories,” the company added in September.

Several Air Force and Space Force missions could benefit from the idea, such as the development of a hypersonic cruise missile or the plan to more widely adopt reusable rockets to bring national security satellites to orbit. The technology may also bring to life a vision of an orbital economy where spacecraft can take off and land like commercial aircraft in the span of a few hours.

Sweating can allow hypersonic systems, or those that travel at five times the speed of sound and can change direction, to move faster and “perform more aggressive maneuvers,” Canopy said. The U.S. is racing alongside Russia and China to build an arsenal of hypersonic weapons that can strike anywhere in the world within hours.

Current state-of-the-art technology isn’t fully reusable because it relies on heat-resistant ceramic tiles like those employed by the U.S. space shuttle program and SpaceX’s Starship, Ifti said.

The tiles can be damaged during reentry, when space vehicles can reach up to 25,000 mph, or 36 times the speed of sound. Inspecting the tiles and replacing those that are damaged may take as long as six months, Ifti said.

Perhaps the most notable example of the tiles’ limitations is the Columbia space shuttle disaster in 2003, when a piece of foam insulation broke off of the shuttle’s propellant tank and hit its left wing. The impact damaged or knocked off some of the tiles that were designed to keep the shuttle from overheating. The shuttle broke apart upon reentering the atmosphere over Texas, killing all seven crew members onboard.

More than two decades later, “the dream is full reusability” of space vehicles, Ifti said. Advances in materials and 3D printing could finally make that dream a reality “within a few decades,” added Ifti, who has worked on transpiration cooling in the U.S. and United Kingdom.

The technology could also assist commercial hypersonic jets, like a “next-generation Concorde” that could fly from New York to Tokyo in less than two hours, Ifti said. Venus Aerospace, a Houston-based startup working on hypersonic flight, announced May 14 it had successfully tested an engine that could allow aircraft launched from conventional runways to reach Mach 5 or 6, compared to commercial airliners that average cruising airspeeds slower than sound.

“At those speeds, you have to think about the heating problem on the nose and the leading edges of the wings, and that’s where you could use transpiration cooling,” Ifti said.

The Physics of ‘Sweating‘

Ifti likened transpiration cooling technology to the way a puffer jacket creates a barrier of air that traps heat in and keeps cold out. Similarly, a layer of gas around a returning spacecraft stops temperatures as high as 10,000 degrees Celsius from reaching the vehicle.

Canopy Aerospace’s 3D-printed materials are already being tested in Texas A&M’s state of the art wind tunnels. The university has several wind tunnels for testing hypersonic flight materials, Ifti said. He argues advances in testing is the third factor, alongside new materials and 3D printing, that can make transpiration cooling a reality.

Those diagnostic tools have come a long way in recent years, he added. For instance, the cameras used to record the experiments in the A&M wind tunnels captured up to 7 million frames per second. “We can see things that our colleagues a decade ago could not,” Ifti said.

The data collected helps Ifti and his colleagues understand how gases behave at high speeds and temperatures, particularly as air grows more turbulent for a vehicle approaching Earth.

Following wind tunnel testing of Canopy’s material, the joint team aims to build a mock vehicle no longer than 1 meter by the end of the year, Ifti said.

The model will have reservoirs of thermally protective gas spread throughout the spacecraft that “sweats” out through porous material, Ifti said.

By the time the project concludes next year, the lessons learned could inform how engineers build a model for flight testing.

“The dream is a flight test,” Ifti said. “But that’s not cheap.”

The post Can Spacecraft Sweat? New Tech Could Make Them Reusable appeared first on Air & Space Forces Magazine.

Air, Space, Technology, AFRL, Air Force, Air Force Research Laboratory, Canopy Aerospace, Hassan Saad Ifti, hypersonic, research and development, reusable spacecraft, Space Force, transpiration cooling

Air & Space Forces Magazine

Bitcoin

Ethereum

Monero

Donate Bitcoin to The Bitstream

Scan the QR code or copy the address below into your wallet to send some Bitcoin to The Bitstream

Donate Ethereum to The Bitstream

Scan the QR code or copy the address below into your wallet to send some Ethereum to The Bitstream

Donate Monero to The Bitstream

Scan the QR code or copy the address below into your wallet to send some Monero to The Bitstream

Donate Via Wallets

Select a wallet to accept donation in ETH BNB BUSD etc..