Following the iPhone 17 event earlier this week, Apple marketing chief Greg Joswiak and Apple hardware engineering chief John Ternus did an interview with Tom’s Guide‘s Mark Spoonauer to discuss the iPhone Air. During the interview, Joswiak demonstrated the iPhone Air’s durability by handing Spoonauer an iPhone Air and encouraging him to try to bend it.

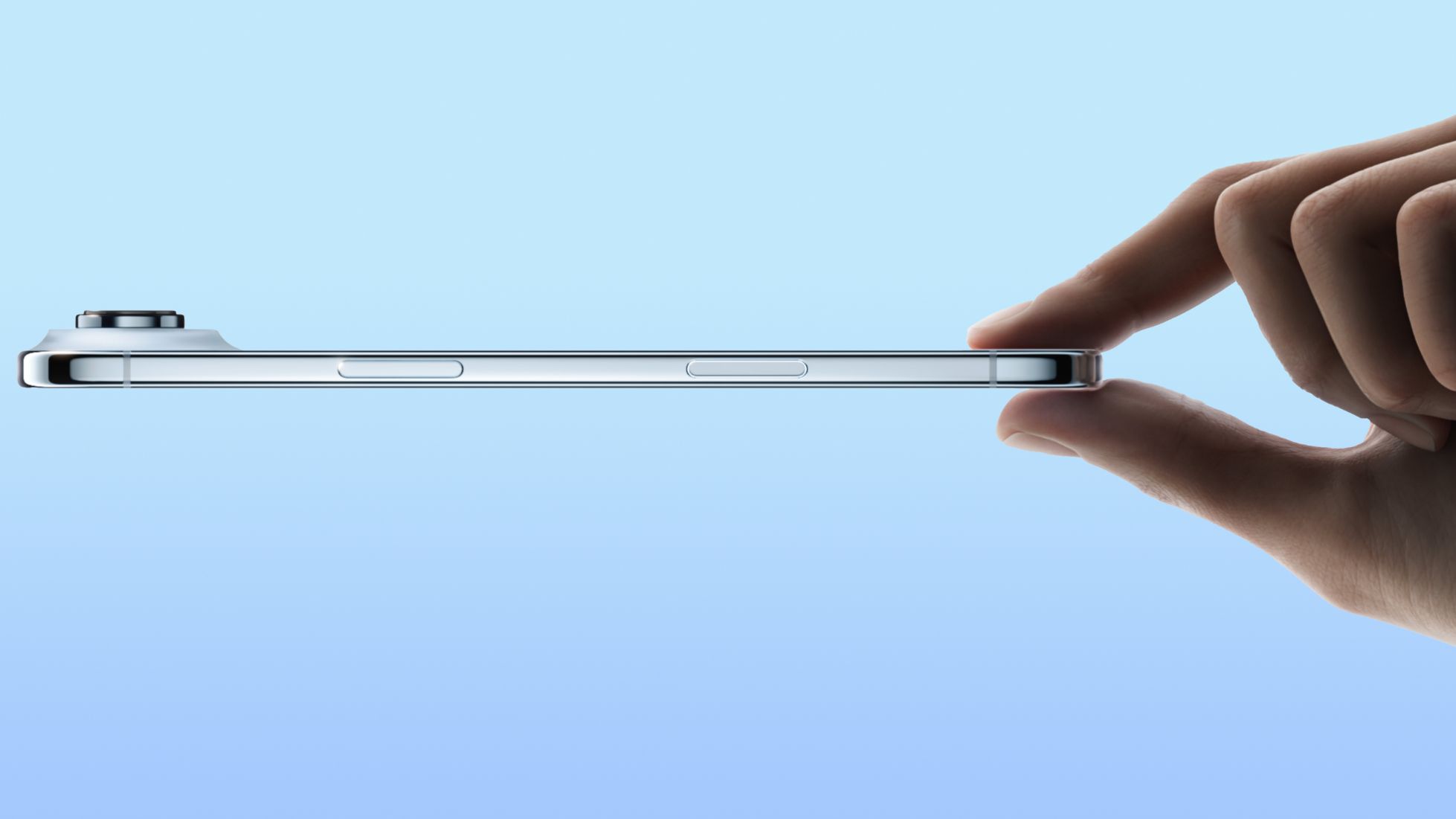

Spoonauer says that it survived the bend test. “I used all my strength, and the 5.64mm thin phone bowed (slightly), but did not break,” he said. TechRadar‘s Lance Ulanoff was also part of the interview, and he too was unable to get the iPhone Air to bend. It did flex, but it returned to its original position, which Joswiak said was meant to happen.

The 6.5-inch iPhone Air has a grade 5 titanium frame, and with the iPhone 17 Pro models transitioning to aluminum, it’s now Apple’s only titanium iPhone. When announcing the iPhone Air, Apple said the titanium frame “exceeds” its “stringent bend test requirements.”

The bendability of an iPhone has been something people pay attention to since the 2014 launch of the iPhone 6 models. The iPhone 6 and iPhone 6 Plus became famous for “bendgate” after users found that the iPhones could bend in a pocket.

According to Ternus, multiple factors needed to align for Apple to design a thin and light iPhone. “We needed advancements in our materials development, Ceramic Shield on the back to be able to create that hollow plateau. If you look at the inside of the iPhone Air, almost the entire phone is living right up there in that top and that in that plateau. And then we need the efficiency of Apple silicon. So it was all of these pieces that had to come together,” he explained.

Spoonauer says that he asked about the “plateau” naming for the camera bump, and it’s a word that Apple has been using internally “for a while.”

The interview continued with TechRadar, where Ternus and Joswiak discussed the iPhone 17 Pro models.

Apple set out to make the iPhone 17 Pro models the “most Pro phones” possible, leading to improvements in battery life, new camera technology, and durability. On the transition from titanium to aluminum, Ternus said there were “two undeniable wins for aluminum.” Apple used a custom aluminum alloy, and it is 20 times better at thermal conductivity than titanium so it is better able to spread heat. Aluminum is also lighter than titanium, which allowed for more battery weight. “And then the icing on the cake is it allowed us to anodize it,” said Ternus, referring to the Cosmic Orange iPhone 17 Pro.

“Look, for years we’ve had Pro customers say ‘Hey, how come the other part of the line gets all the fun colors, you know, and we don’t?’ And it’s like Okay, you want a fun color? How about Cosmic Orange, baby?” Joswiak said.

Both interviews are worth watching for those who are interested in additional details on the iPhone Air and the iPhone 17 Pro models. Apple’s new devices will be available for pre-order starting on September 12, with a launch planned for September 19.

This article, “iPhone Air’s Durability Put to the Test by Apple Execs” first appeared on MacRumors.com

Discuss this article in our forums

Apple, Rumors, Mac, iOS, iPhone, iPad

MacRumors: Mac News and Rumors – All Stories

[crypto-donation-box type=”tabular” show-coin=”all”]